Gas detection systems provide vital early warning of the presence of dangerous gases in industrial environments, but it is crucial to select and use the right type.

Features

Dangerous gases: getting the monitoring right

The presence, or creation, of toxic, flammable and combustible gases poses a serious risk to the health and safety of people at work. The risks are widespread, and range from leaks of carbon dioxide used in the food packaging industry to seal foodstuffs, to leaks of ammonia used in various manufacturing processes and the water treatment industry.

Inhaling these harmful gases can lead to a variety of ill health effects, ranging from an increased respiratory rate to impaired consciousness, right through to convulsions and asphyxiation. Some gases and vapours also pose a risk of fire or explosion, and another risk arises when the build-up of a gas creates an oxygen-deficient atmosphere, which can cause effects ranging from nausea to loss of life.

UK employers are therefore legally required to eliminate or adequately control the health and safety risks from hazardous gases and vapours. This means, for example, using adequate ventilation systems to remove gases from the air and providing suitable respiratory protective equipment to prevent workers from inhaling dangerous gases.

Another crucial tool in reducing the risks is gas detection and monitoring equipment capable of immediately alerting workers and others to dangerous situations, such as hazardous concentrations of a gas. However, it is crucial that the most appropriate gas detection and monitoring system is selected and used, taking into account factors such as the best way of warning workers about the presence of a gas.

There are many types of gas detection and monitoring systems but, broadly speaking, they can be divided into two categories: fixed and portable.

Portable gas detectors

Portable gas detectors, sometimes referred to as personal gas detectors, are usually compact, battery-powered devices. They are usually worn on a worker’s clothing or belt – though they are sometimes hand-held – and have a variety of safety functions.

They can provide early warning of the presence of a toxic or flammable gas or vapour in the area immediately surrounding the person wearing or using them and can help in tracing low-level and low-risk leaks of flammable and toxic gases before they pose a serious danger. They can also test the atmosphere in a confined space to provide a pre-entry check for hazards like gases or low oxygen levels and provide continual safety monitoring of gases and oxygen levels while working in the confined space.

When a portable gas monitoring device detects that a gas has reached pre-set alarm levels, it will activate an alarm and start flashing. The alarm is designed to be clearly heard and seen by the wearer, allowing them to immediately take action to protect themselves and others – for example, by leaving the danger area.

Fixed gas detectors

A fixed gas detection system can be either an individual detector or a series of detectors that are permanently installed in a workplace, a work area like a confined space or near to certain equipment. They provide continuous monitoring, detection and automatic warning of imminent gas hazards, like a leak or dangerous concentration of a toxic gas. The detectors are usually hard-wired, and connect to a central control panel, although wireless detectors are increasingly being used and avoid the need for hard-wiring the system.

The technology means that multiple fixed detectors monitoring multiple different gases can be installed across a site and all of these are controlled and monitored by the central control panel and software.

If necessary, the detectors can be linked to the site’s building management system. This means that other systems in the building or location – such as the ventilation system for the area – can be automatically linked to the fixed gas detection system’s control panel.

So, if gas levels rise above pre-programmed safe levels, windows will automatically open and extractor fans will be activated in order to help dissipate the gases. Also, a fire alarm will automatically sound so people are warned and instructed to evacuate. A building-wide alarm, like a fire alarm triggered by a fixed gas detection system, also reduces the risk of an individual who is carrying a personal gas detector failing to take appropriate action in the event of their personal alarm being triggered – such as failing to immediately evacuate.

If a fixed gas detection system is connected to systems like the building’s ventilation units, this can also bring cost and efficiency savings. For example, instead of constantly running the ventilation fans for fear of gas readings rising above a potentially harmful level, the ventilation system is only activated when required, as indicated by the readings taken by the fixed monitors.

Fixed and portable (i.e. personal) gas detection devices are often used in combination, but it is crucial that the appropriate type of detector is used for the situation and risk. The table overleaf provides some examples of the type of gas hazards each type of detector can protect against, and the safety benefits they bring.

It is vital that employers get the detector selection process right. For example, a mistake that is commonly made is when a permanent fixed detector is required due to the high and ongoing risk from gas in an area, but instead portable gas detectors worn or carried by individuals are used. A portable detector relies on the individual always using it correctly at the required time, which introduces the risk of human error. In contrast, a fixed permanent detector is always in position and constantly monitoring (provided it is installed, used and maintained correctly). As a result, there is less chance of human error creeping in.

Also, because a portable detector is battery-powered, there is a risk it could run out of power during use if the user (or others like supervisors), fail to properly charge it and check its power level before starting work. In addition, if workers are meant to use portable detectors but the units are not charged and immediately ready and available for use, they can be tempted to enter a high risk area without them.

For example, workers may feel the short time period they will spend in the area means the risk from gas or from oxygen-deficiency is low. Also, operational and production pressures may lead workers to enter the hazardous area straight away instead of waiting until the required personal detectors are available. There have been cases of this happening where carbon dioxide has been present (a largely odourless and colourless gas), and fatalities have occurred as a result.

Also, a portable or personal gas alarm is only designed to alert the wearer and those in the immediate vicinity, and will generally not be sufficiently loud to alert someone located a considerable distance away. In this situation, one or more fixed detectors might be more appropriate.

Simon Hopwood is Account manager, Fixed Gas and Flame Detection, at Draeger Safety UK

For more information see: draeger.com/en_uk/Home

FEATURES

Long working hours in India: debate rages over the impact on wellbeing

By Orchie Bandyopadhyay on 10 March 2025

Calls from high profile leaders of both Indian and global information technology companies for Indian and international workers to work longer hours to boost economic output and speed up the development of AI technology have led to warnings about the threat to workers’ health and work-life balance.

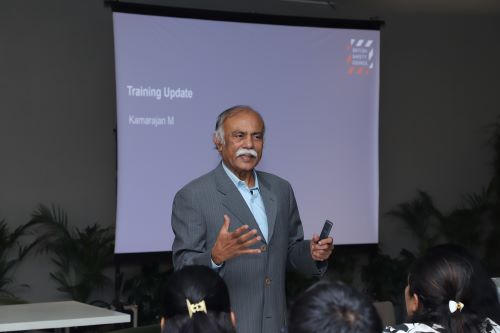

Safety training: top tips for improving its effectiveness

By Marimuthu Kamarajan on 10 March 2025

Health and safety training is a vital tool for improving the safety performance of a business. However, employers must first address any cultural problems that could undermine its effectiveness, such as time pressures encouraging workers to take short-cuts, explains Marimuthu Kamarajan, head of education at British Safety Council.